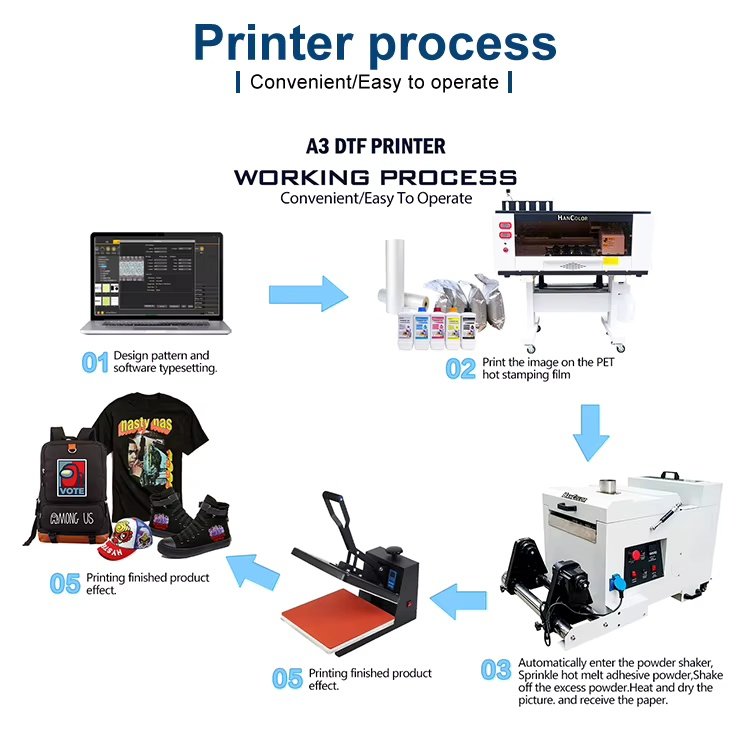

What is DTF Printing Solution

- A DTF (Direct-to-Film) printer is a specialized printer that prints designs onto a special film, heat-pressed onto fabric or other materials, allowing for durable and vibrant prints on various substrates.

Advantages of DTF Printing

- Versatility: DTF (Direct-to-Film) printers work on virtually any fabric type—cotton, polyester, blends, and even non-textile materials like wood or leather—unlike traditional methods limited to specific substrates.

- High Quality & Durability: They produce vibrant, detailed prints with excellent wash resistance, ensuring long-lasting designs without cracking or fading.

- Cost-Effective for Small Runs: Eliminates the need for expensive screens or plates, making short-run orders affordable and reducing waste.

- User-Friendly: Minimal pre-treatment steps and no post-curing required, streamlining workflows for beginners and professionals alike.

- Soft Hand Feel: Prints retain fabric flexibility, avoiding the stiff texture common in other transfer methods.

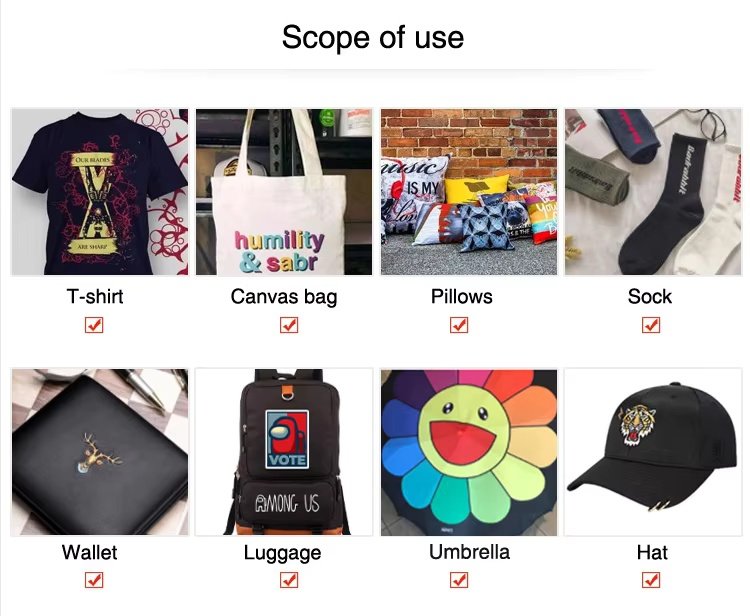

Applications Industries

- Fashion & Apparel: Custom T-shirts, sportswear, and athleisure wear.

- Promotional Products: Branded merchandise like bags, hats, and accessories.

- Home Decoration: Printed cushions, curtains, and table linens.

- Footwear & Accessories: Unique designs on shoes, backpacks, or phone cases.

- Industrial Uses: Labels, signage, and technical textiles.

Market Outlook

- DTF printing is rapidly gaining traction due to rising demand for personalized products and on-demand manufacturing. Its eco-friendly potential (reduced water/ink waste compared to DTG) aligns with sustainability trends. Advances in ink technology and automation will further boost efficiency, positioning DTF as a go-to solution for small businesses and large-scale producers alike. With limitless creative possibilities and lower entry barriers, the DTF industry promises robust growth in the global print market.