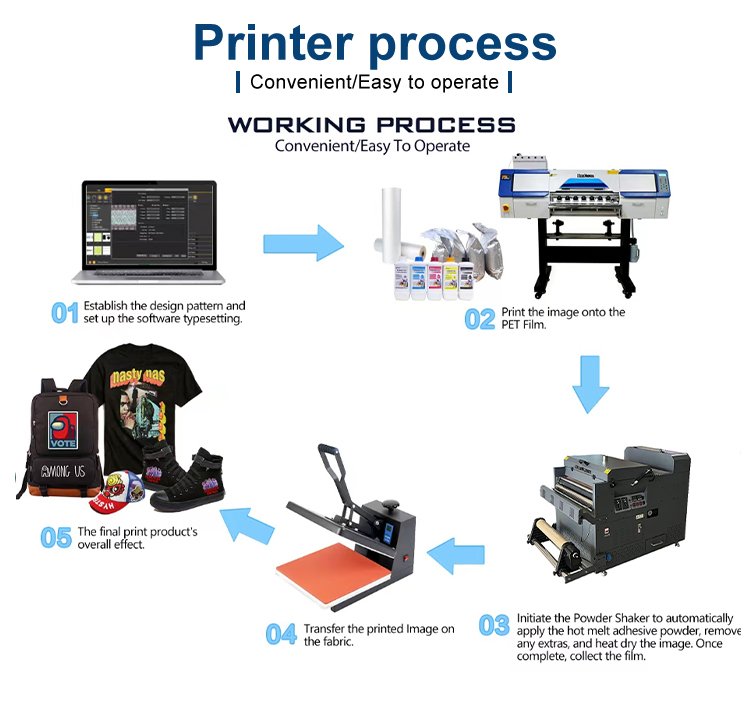

What you need when the DTF printing applicaiton for custom clothing printing industry

- DTF Printer/ PET film/ DTF Pigment ink/ Hot-melt adhesive powder/ Heat press machine or curing oven/ DTF printing software

The core advantages of direct-to-film

- Wash fastness – these transfers lasting like screen printing

- Flexibility of materials – you can apply DTF printer transfers to any fabric

- Very low application time – in most cases, transfer application to a t-shirt is a 15-second heat press

- VERY high-speed production

Applications Industries

Fashion & Apparel: Custom T-shirts, sportswear, and athleisure wear.

Promotional Products: Branded merchandise like bags, hats, and accessories.

Home Décor: Printed cushions, curtains, and table linens.

Footwear & Accessories: Unique designs on shoes, backpacks, or phone cases.

Industrial Uses: Labels, signage, and technical textiles.

Market Outlook

DTF printing is rapidly gaining traction due to rising demand for personalized products and on-demand manufacturing. Its eco-friendly potential (reduced water/ink waste compared to DTG) aligns with sustainability trends. Advances in ink technology and automation will further boost efficiency, positioning DTF as a go-to solution for small businesses and large-scale producers alike. With limitless creative possibilities and lower entry barriers, the DTF industry promises robust growth in the global print market.